GBS High temperature tapes are mainly apply for the processing of Aerospace industry, Electrical&Electronic industry, Powder coating/painting industry, etc, with working temperature resistant to 300℃, GBS heat resistance tapes are including Polyimide tapes, PET Silicone tape, PTFE Teflon tape, Glass cloth silicone tape, these tapes could be converted into different shape die cutting as different requirement from customer.

-

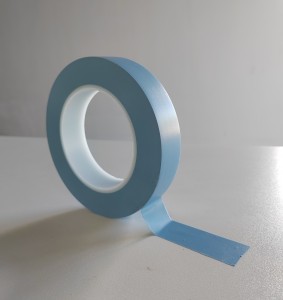

Nichiban 535A Analogue PVC Fine Line Masking Tape for Auto Painting Process

Our high temperature PVC Fine Line Masking Tape is equivalent to Nichiban 535A, 3M 4737, Tesa 4174, Tesa 4244, which is specially design for broad curves and straight lines color separation on automotive painting and two-tone car body masking. It uses flexible and durable polyvinyl chloride PVC film as carrier and coated with natural rubber adhesive. The tapes has excellent features with high temperature resistance, which is up to 180ºC for 1hour, and can be easily to peel off without leaving residues on the body. It also has very strong peel adhesion and good conformity to adhere on both smooth or uneven surfaces to provide excellent color line separation and masking in high-temperature auto painting processes.

The temperature it resists is upper than the 4174 PVC Fine Line Tape we are manufacuring as well.

-

DMD Insulation Paper for Transformer&motor Gasket Insulation

DMD Electrical Insulation Paper is a type of composite flexible material which made of two layers of electric non-woven polyester fabric with polyester film in the middle and coated with high temperature resistance F-grade adhesive. It has high mechanical strength, excellent electrical property and long operation temperature resistance at 155℃. It’s suitable for general F-class motors as slot, phase insulation and gasket insulation on various industries like electronic and electrical industry, wire and cable industry, automotive manufacturing industry, etc.

Our thickness range of DMD insulation paper is from 0.16mm to 0.46mm, and color is available with white and blue. Size can be customized according to customer’s application.

-

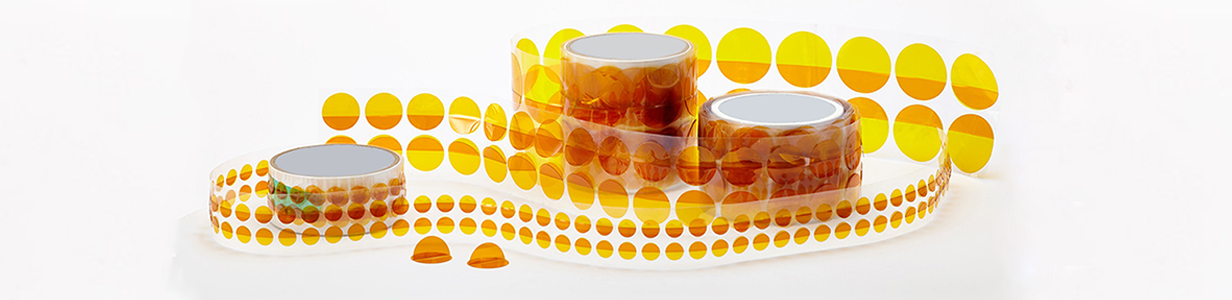

High Heat Kapton Poylimide Tape for PCB Processing

GBS Kapton polyimide tape uses polyimide film as substrate coated with single side or double side high performance organic silicone adhesive. Capable of wide temperature range from -260°(-452°F ) to 260°(500°F), such high heat polyimide tape can be used in high temperature working temperature on printed circuit boards during wave solder or reflow soldering, SMT surface mounting, Transformer manufacturing, as well as lithium battery positive and negative and ears fixed. It has been widely used in Aerospace, aviation, marine, spacecraft, missile, rockets, atomic energy, electrical and electronic industry and other fields.

Color options: Amber, Black Red

Polyimide film thickness options: 12.5um, 25um, 35um, 50um, 75um. 100um, 125um.

Available roll size:

Max width: 500mm(19.68inches)

Length: 33meters

-

Die Cutting Nomex Insulation Paper Nomex 410 for Electrical Industry Insulation

Dupont Nomex 410 is a unique aramid enhanced cellulose material, composed of high quality electrical grade cellulose pulp. Among the Dupont Nomex family, Nomex 410 is a type of high-density product as well as high inherent dielectric strength, mechanical toughness, flexibility and resilience. It has various ranges of thicknesses ranging from 0.05 mm (2 mil) to 0.76 mm (30 mil), with specific gravities ranging from 0.7 to 1.2. Featuring high temperature resistance and excellent dielectrical strength, Nomex 410 can be applied to most of electrical industry insulation, like transformer insulation, large power, medium voltage and high voltage industry insulation, motors insulation, battery insulation, power switch insulation, etc,.

-

Copper Clad Polyimide Film Single Side FCCL Sheet for FPC Board Assembly

Copper Clad Polyimide Film uses amber or black polyimide film as base film and plated with copper foil tape. It’s usually used together with thermosetting coverlay film on Flexible Printed Circuits boards industry, featuring excellent high temperature resistance and insulation performance. The soldering resistance temperature is 288℃ without bubbles and delamination. We have complete series products of PI base FCCL and polyimide thermosetting coverlay and polyimide stiffener sheet, which can provide professional solutions for FPC Board assembly or other heat resistance and electrical insulation manufacturing industry.

-

Double Side Kapton Tape for Electronic Component Manufacturing

Double side polyimide kape tape use polyimide film as carrier with double side silicone adhesive coated. It can be widely used in the manufacturing of electronic industry, automotive industry, SMT Surface fixing, lithium battery processing.

Thickness is available from 50um-175um as per client’s requirement.

General size is 500mm width and 33meters length.

Besides of that, Single Side Kapton Tape and Kapton Film with No Adhesive is available.

-

Skived heat resistant PTFE teflon Film for electrical insulation

Skived PTFE Film is consist of suspension PTFE resin by moulding, sintering, cooling into blank, then cutting and rolling into film. PTFE film has excellent dielectric properties, ageing-resistance, corrosion resistance, flame resistance, high lubrication and excellent chemical corrosion resistance.

Color options: White, Brown

Film thickness options: 25um, 30um, 50um, 100um

-

Fireproof Flame Retardant Double Sided Tissue Tape for Membrane Switch

GBS fireproof flame retardant double sided tissue tape uses thin tissue as carrier and double coated with environmental halogen-free flame retardant adhesive and combine with release paper. With the strong adhesion and flexibility, fireproof double side tissue tape is usually applied on fixing and bonding of membrane switch, lithium battery fixation, fixing the thermal insulation panel for automotive engine. It can also be laminated with other materials like Foam, EVA, PC, PP to meet different industry application.

-

High Temperature Resistant Sublimation Tape for Tumbler Sublimation Print

The heat resistant Sublimation Tape is made of polyester film and then coated with high performance silicone adhesive. With smooth surface and high insulation, the strong organic silicone adhesive is easy to adhere with no residue after peeling. It’s mainly used to hold transfer sheets in place while sublimating onto a variety of items including ceramic mugs, tiles, metal award plaques, polyester T-shirts, mouse pads. It can minimize shrinkage after baking and also clean removal while peeling off. The sublimation tape is not only suitable for sublimation on coffee cups, but also suitable for heat transfer vinyl on T-shirts, pillows, clothing, fabrics, and also can be applied for most kinds of DIY projects.

-

Poylimide Sublimation Heat Transfer Tape for Sublimation on Coffee Mugs, HTV Craft on T-Shirt Fabrics

The sublimation heat tape is made from polyimide film as carrier and coated with silicone adhesive. It is easy to stick and not easy to break while peeling. It’s compatible in a wide temperature range of up to 280°C (536°F). It offers excellent heat resistance and chemical resistance properties, and it’s easily to peel of without leaving residue. Even uneven surfaces can be easily wrapped with heat resistant craft tape. Heat transfer tape works well in coffee mug press, heat press, T shirt application or other Thermal transfer printing.

-

Optically Transparent Teflon FEP Release Film for DLP SLA 3D Printer

FEP film (fluorinated ethylene propylene copolymer) is a hot melt extrusion cast film made of high-purity FEP resin. Although it is lower melting than PTFE, it still maintains a continuous service temperature of 200 ℃, as FEP is fully fluorinated like PTFE. With over 95% light transmittance, FEP Film ensures high stability of UV lightning to cure liquid resin during the whole printing process. It’s non stick and has excellent electrical properties, high chemical stability, low friction, excellent long term weathering and very good low temperature properties. FEP Film is usually applied on DLP or SLA 3D printer, and placed in the bottom of the printing VAT between your UV screen and the 3D Printer build plate to allow the UV rays to enter and cure the resin.

-

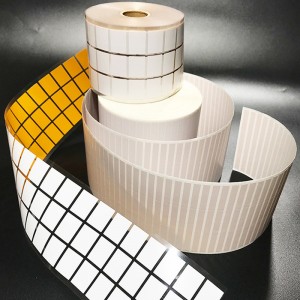

High Temperature polyimide thermal transfer label for PCB bar code tracking

Our polyimide high temperature label uses 1mil or 2mil polyimide film as carrier coated with acrylic pressure sensitive adhesive.The matte white thermal transfer topcoat is easy to read for all kinds of bar codes and other variable information. It can withstand short high temperature up to 320°and long term temperature to 280°. It has very excellent thermal stability, moisture resistance and good initial tack, which can be applied on various application such as PCB Board tracking, other bar code tracking, surface protection and masking like wave solder masking, SMT processing, lithium battery or chip packaging protection.