High-end Thermal Conductive Silicone Gasket Composite PI Film for Heating Power Devices

| Material | Thermal silica |

| Color | Grey/blue |

| Thermal conductivity | 1.0±0.2W/M.K |

| Hardness | 45±5Shore C |

| Breakdown voltage | >6Kv/mm |

| Volume resistivity | 10^14Ω.cm |

| Flame retardant grade | 94V-0 |

| Environmental testing | Pass |

Features

1. Polyimide film and silicone rubber provide excellent electrical isolation and high dielectric performance

2. Silicone rubber layer provides a compliant, non-stick surface for excellent heat transfer and easy disassembly

3. Polyimide film provides excellent cut-through resistance

4. Thickness: 0.5mm~3mm (±0.2mm); 3mm~5mm (±0.3mm); 5~20mm (±10%mm)

5. Color: can be customized

6. Thermally conductive adhesive provides excellent thermal transfer at low application pressures

7. Certain cache performance and flame retardant and insulating properties

8. The material is stable and does not produce foreign matter

9. Available to die cut into any shape design as per drawing

Served Industries:

1. T laptops, computer hosts, TVs, monitors and other display products;

2. High-power LED lighting, high-power LED spotlights, street lights, fluorescent lamps, etc.;

3. Power devices (power supply, computers, telecommunications), automotive electronic modules (engine wipers) power modules, high-power power supplies, computing server applications (CPU, GPU, hard drives) and anywhere cooling needs to be filled;

4. Various power battery packs;

5. Used in heating power devices (integrated circuits, power tubes, thyristors, transformers, etc.) and heat dissipation facilities (heat dissipation) for electronic products and electronic equipment.

sheets, aluminum shells, etc.) to achieve better thermal conductivity.

-

Equivalent to 3M 8310 Environmental Shopping Ca...

-

Heavy duty clear double sided acrylic foam tape...

-

Custom Converting Full Series of Foam Tape Roge...

-

3M Double Sided VHB Tape( 9460PC/9469PC/9473PC ...

-

Die cutting 3M VHB series 4910 4941 4611 5952 F...

-

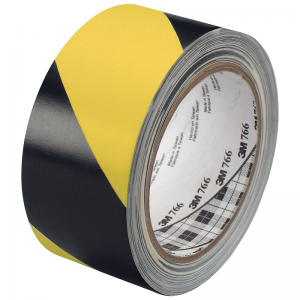

3M 766 Safety Stripe Vinyl Yellow and Black Tap...