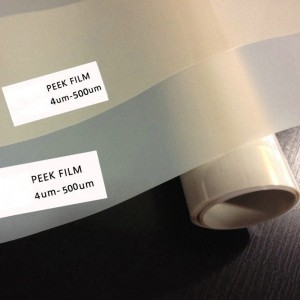

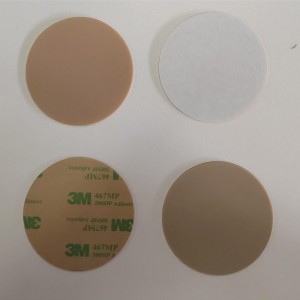

High Temp Polyether Ether Ketone (PEEK ) Film Material for Engineering Applications

| Item | 100% PEEK | PEEK+30% carbon fiber | PEEK+30% glass fiber | PEEK+30%

(carbon fiber+graphite+PTFE) |

PEEK+20% PTFE |

| Tensile Strength(MPa) | 95 | 250 | 175 | 145 | 70 |

| Bending Strength(MPa) | 155 | 350 | 268 | 220 | 118 |

| Compressive Strength(MPa) | 118 | 300 | 247 | 170 | 103 |

| Melt Point (℃) | 343 | 343 | 343 | 343 | 343 |

| Dielectric Strength (KV/mm) | 18 | / | 19 | / | 20 |

| Density (g/cm³) | 1.3±0.02 | 1.4±0.02 | 1.5±0.02 | 1.43±0.02 | 1.41±0.02 |

Features

• Heat resistance, wear resistance, and fatigue resistance

• Creep-resistant

• Physically light yet highly resistant to corrosive substances

• Produce parts with tight tolerances

• Corrosion resistance

• Good interlayer bonding strenth

• Dimension stability

• Impact resistance and high strength

Application:

• Medical Industry

• Aerospace and military

• Food processing and filling machine

• Analytical instrument

• Semiconductor industry

• Oil&gas, petrochemical machinery industry

• Textile machinery industry

-

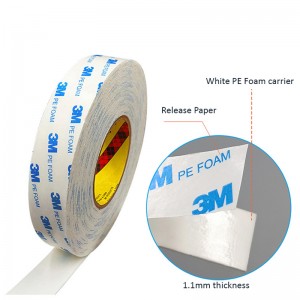

Double Coated 3M 1600T PE Foam Tape for General...

-

Polyester Die Cutting Tape with Wishbone Handle...

-

Custom Converting Full Series of Foam Tape Roge...

-

3M 300LSE Adhesive 9495LE/9495MP Double Sided P...

-

Medium Firmness Silicone Foam Rogers Bisco HT-800

-

Ultra-Thin Nano Aerogel Film with 0.02W/(m.k) L...